A version of this article ran in the September issue of Bicycle Retailer & Industry News.

JIANGSU, China (BRAIN) — The e-bike industry is amid a tightening battery pack market with many cell suppliers putting manufacturers on allocation, resulting in longer lead times and the potential for higher prices.

Pack manufacturers have been challenged with a shortage of lithium-ion battery cells since the beginning of the year. Reasons include booming electric vehicle and electric tool markets, and the COVID-19 effect on workforce productivity.

"Moreover, we have to consider another factor: The e-bike brands may place orders more than what they need," said Luc Liu of Phylion Battery Co. in Jiangsu. "For instance, you need only 10,000 batteries, but you worry about the supply of the battery pack, so you place orders three times 10,000 or three times 5,000 to three different battery-pack suppliers, because it's uncertain for you which of them can supply timely and enough. Such operation strengthens, more or less, the feeling of shortage."

Liu is general manager of the Phylion e-bike battery division, one of the largest global suppliers.

He said electric car company Tesla has drained the battery market, noting that one electric vehicle requires enough cells to make 100 e-bike battery packs.

He also noted battery manufacturer Samsung acquired a new electric vehicle customer, Rivian, "which takes an important share of Samsung SDI production capability," Liu said.

TTI — parent company of cordless tool brands Milwaukee, AEG, and Ryobi — and the Bosch cordless tool division have increased demand on battery-pack manufacturers as well.

"Moreover, COVID-19 impact is another factor," Liu said. "Samsung SDI Malaysian cell factory has been (affected) by COVID-19, and production output decreased. In the meantime, the designed production capability of the three giants — Samsung SDI, LGC and Panasonic — has not expanded in the past years."

Consequently, Liu said, the Korean and Japanese cell suppliers have not been able to meet e-bike battery demand, with Samsung, LG Chem, and Panasonic halting production of some cells.

"According to predictions, the shortage will continue until at least H2 of 2022," Liu said.

He added Phylion will be relying more on Chinese brand cells. Last year, Chinese brand cells were used for 5% of Phylion's e-bike battery packs. This year, it's increasing to more than 30%.

"But such a switch has a lot of cost and time," Liu said. ... It's not simply to change the cell in production; we have to test the packs, get a certificate before mass production. It takes 10~20 weeks. In case we have many models for such change, it consumes huge engineering work and money."

Liu said a less-expensive battery pack doesn't necessarily mean poorer quality, but a brand needs to know why a pack costs less and always deal with a reputable supplier.

Shortages could lead to higher prices, but not until next year, Liu predicted.

"It's difficult to say how much it will rise because of the uncertainty of many factors," Liu said. "From Q4 of 2020 to Q3 of 2021, the battery pack price has risen 10-20% due to the cost increase of cells, chips, and other materials. I'm a little bit optimistic that the battery pack price will rise less than 10% (by) 2022. I cannot say my view will be very correct. Let's see what will happen."

Bob Margevicius, Specialized Bicycles executive vice president, said battery manufacturing is very capital intensive, with few cell producers globally. "Safety and integrity concerns drive most users to well-respected brands with limited — but growing — appetite for local China made cells," Margevicius said. "Much like the microprocessor shortage, this limited supply will be with us for months to come, and until there is more production or alternatives to service growing global needs."

Mike Fritz, chief technology officer of Human Powered Solutions, said he's heard of no impending battery pack shortages, but three industry experts he contacted reported demand for cylindrical lithium-ion cells used in e-bike battery packs has never been higher.

"While shortages are not an issue now, it's conceivable that it could be a problem in the future," Fritz said.

Having long-term supplier relationships has helped e-bike manufacturers Pedego and Vvolt avoid shortages.

"Every day brings new supply-chain challenges ever since last spring when that insidious virus wreaked havoc on the world," said Pedego CEO Don DiCostanzo. "But Pedego has been able to provide our now 200 stores with a steady stream of our products, including batteries."

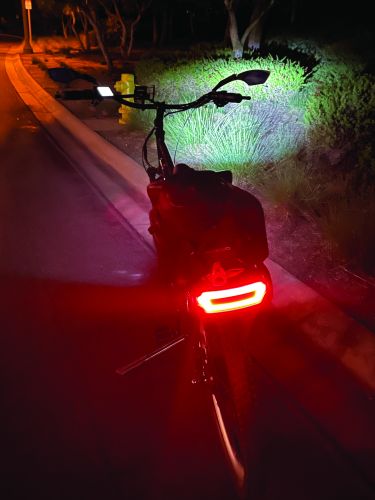

In fact, DiCostanzo said, despite the challenges, Pedego recently launched its third-generation battery that incorporates several improvements, including a rear wraparound taillight with turn-signal and brake-light capabilities.

Mike McBreen, the COO of Rad Power Bikes, said demand from electric vehicle and tool makers is straining the capacity of battery makers. He said Rad Power has long term commitments from major cell and pack suppliers. "We had to move quickly; we don't take that concern lightly," he said.

New direct-to-consumer Vvolt also has secured a reliable partnership with Taiwanese battery pack supplier Celxpert. Kyle Ranson, Showers Pass owner and Vvolt founder, previously worked in the high-tech sector with Compac and HP and knew the benefit of establishing the right battery vendor relationship.

"They really got started in the early days of supplying lithium-ion to the PC vendors, batteries for notebooks, etc.," Ranson said. "I was aware of them because of my previous life, and so when they hit the radar, it's going to be critical that we align ourselves with somebody who's been around the street. Their supply chain is mature. We believe we're in a pretty solid position. The whole supply chain is a complete mess right now. At least on the battery side, we're in pretty good shape."