Editor's note: The story has been updated to reflect that VAR is apparently not the first tool brand to offer a facing tool with dual cutting heads.

PHILADELPHIA (BRAIN) — VAR Tools has literally been on the cutting edge of quality bicycle tools since 1945 in Gellainiville, France. So there was some buzz at the Philly Bike Expo on Saturday over the debut of the second-generation Disc Brake Mount Facing Tool on display with curious onlookers watching it in action.

Wayne Bingham, owner of Mel Pinto Imports of Lovettsville, Virginia, is the U.S. VAR Tools distributor. A former retailer and self-described "bike tool nerd," Bingham showed off the first-generation facing tool for frames and forks at the 2016 Expo. Returning this year with the improved version was a full-circle moment.

When the original tool was being developed, Bingham wondered if there would be a market for it. He found out quickly there was as the 2016 Expo approached.

"I literally got it two weeks before the show," said Bingham, who added that while there are other facing tools in the market, VAR's is the only one with dual heads that cut simultaneously. "I actually started getting cold calls from my customers asking about the tool because they were saying they needed a tool like this."

(An industry member has pointed out that the German tool brand Cyclus has offered a tool with dual heads for many years. Cyclus does not appear to have a U.S. distributor, but the tool can be seen on its website.)

Having two heads cutting into the mount at the same time was a breakthrough because other tools faced only one bolt mount at a time. That requires carefully measuring for evenness. "You have to go back and forth, and you'll never get that accurate," Bingham said.

In the nine years since, VAR's second-generation facing tool has been upgraded in several ways, including improved coated heads for more precision. It's time to forget about using metal files.

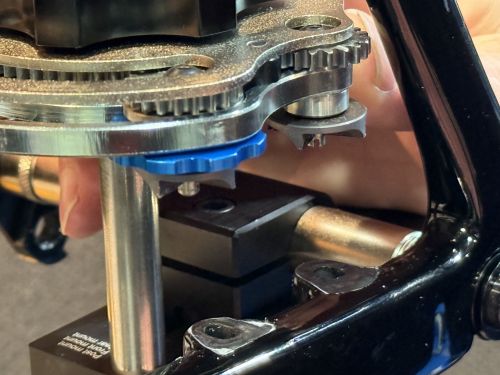

"Everything in here has been reduced inside in size, made more accurate, so there's more efficient movement within the gears," said Bingham, noting the new cutting heads can be purchased as an upgrade to the first-generation facing tool.

The new facing tool is available to dealers through MelPintoImports.com for $584, plus shipping. It comes in a carrying case with two sets of two cutters, and adapters for compatibility with different thru-axle and quick-release standards.

Like many standards in the bicycle industry, disc brakes have been evolving, with three — IS, post, and flat mount — in use. VAR's tool will work on all and also on frames and forks made of carbon fiber, steel, aluminum, and magnesium. Facing mounts is a necessary task for retailers to ensure perfect flatness and parallelism to avoid rotor rub and the ensuing and dreaded brake squeal.

Bingham said when Shimano debuted the flat mount design, it made a quality facing tool even more necessary for shops.

"Several years ago, Shimano actually bought 17 from us because their tech reps were getting shop calls because customers were complaining about brake squeal. Shops were saying we have a problem with the brakes, and Shimano said it's not the brakes. The brake has a very tight tolerance by design. It's the problem with the frame, and we can show you."

He further explained that flat mount holes are closer together than IS and post mount.

"When Shmano designed the flat mount, they compressed all of that and made the two points closer together, which compounds the problem of them being out of alignment. The farther apart they are, the more space you have to level. So it wasn't as much of a problem as it was when everything went to flat mount."

Acquiring the distribution business in 2008 from well-known U.S. importer Mel Pinto in 2008, Bingham was excited to bring VAR Tools to the U.S. as a former dealer understanding the need for quality shop tools.

"I saw an opportunity with VAR because I had friends, worked in shops, and I went to shops when they went out of business and bought tools. I knew VAR Tools as having a great reputation for quality and longevity. Since that time, I have become VAR's sole importer in the United States."