TAICHUNG, Taiwan (BRAIN) — SRAM has expanded its Asia headquarters in the past 29 years, adding 17 buildings and stretching out to 452,000 square feet. Its latest addition is a small classroom but said it believes the space is every bit as far-reaching as the previous expansions.

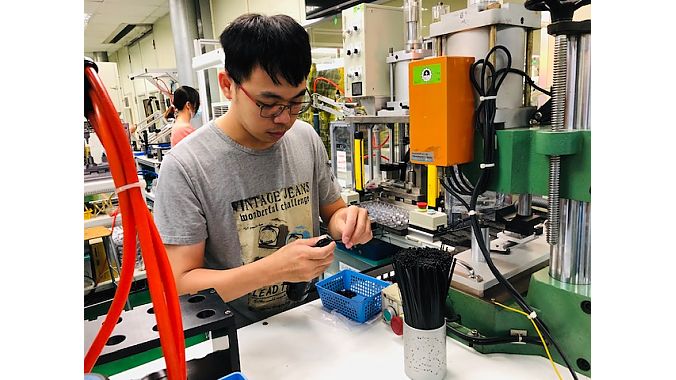

The Taiwan Manufacturing Training Center opened this month to not only train new employees but to give current employees a place to cross-train for additional assembly lines in a controlled environment. Instruction focuses on safety, quality production and continual improvement process.

Bob Chen, SRAM Asia GM/engineering manager, said Monday during a factory tour that cross-training is encouraged and rewarded with increased pay.

"This is really good for career development," said Chen, who added SRAM has worked the past two years to improve efficiency. That has led to doing more with less and resulted in the Asia workforce losing about 100 jobs. Before the center opened, Chen said new employees had to learn on the floor.

"We want to develop our own training capability and skills for our employees," Chen said.

Joao Pires, SRAM's director of manufacturing, said not only do shop floor employees have to attend training, but managers, too: three days in all.

"We need to do this so we have have the right skills and we're speaking the same language," Pires said. "If you look at our products, the electronics and other parts, we need to train people ourselves."

SRAM has 2,405 employees in all the Asia factories, 2,122 in Taiwan. Globally, it has 3,102 workers in 18 locations in nine countries. It has "dramatically" ramped up output capacities, Chen said, not by automation, but by efficiency.

And don't look for SRAM adding mass automation in the near future. "When you invest in robots, they are good at mass production, but they are also inflexible," Pires said. "So, anytime you want to change your product or production, you have a big investment making robotics. That kind of limits your innovation. We believe more in how flexible can we be and how quickly we can make the product. We want small flexible machines to make our product."

SRAM has a 30-day turnaround on product orders, Chen said.

Pires said SRAM's Asia marketing manager, Kennth Xu, has been instrumental in implementing the company's continual improvement process.

"We need involvement from everyone on the shop floor," Pires said. "We have about 1,500 team members on the shop floor. If everyone of them comes up with an improvement idea, we have 1,500 improvement ideas. That's different than if you bring it from the management on down. If you have only a couple of managers trying to improve, it won't have an effect. That's why that training center (was created). How do we make our team better? We involve everyone."

Responding to a question about SRAM's interest in e-bikes, Chen said while it maintains a good relationship with motor suppliers to supply drivetrains, there are no plans to develop a motor "at this moment. We are paying attention to e-bike development."

SRAM also is monitoring the trade war, but so far it hasn't been affected. "I would say the whole Asia area probably, and our customer (has been affected)," he said. "Manufacturing has moved here, so we need to pay attention to that."