TAICHUNG, Taiwan (BRAIN) — Being a viable alternative to Shimano is not easy for the small Taiwanese company MicroShift. Not only is it in the prototyping stages of its own electronic drivetrain development, but it recently invested in a huge forging machine for cog production to offer its first cassettes.

Then you add Shimano changing its cable-pull ratio for mountain bike 10-speed, now different from road 10 and 11-speed, and pile on mountain bike single-, double- and triple-chainring options and the task of being an option to Shimano is daunting.

“If a product manager wants to do something other than Shimano we want to be there with an alternative. And we want to have our own reputation for quality and shifting performance established so the decision to choose us is easy,” said Jerry Lai, MicroShift’s vice president.

Lai said it has been a slow process to build up its reputation but the company’s sales have grown steadily and it's picking up additional spec for 2015, most notably on some Specialized and Quality Bicycle Products (QBP) bikes at the Shimano 105 level in the U.S. market. With the increasing spec comes more pressure to expand its drivetrain products.

“For years when product managers asked me what cassette I recommend for our shifters I said Shimano, they are just the best. But when some product managers want to do a non-Shimano bike, they don’t want any Shimano on it at all, so they kept pressuring us to offer a cassette,” Lai said.

The company’s first cassette offerings will be for road, though these days they are little different from mountain bike cassettes.

“Most of the requests we get for road cassettes are for 32-tooth big cogs for compact road drivetrains. No one wants to be seen riding a triple, but everyone wants a triple’s gear range,” he added. Knowing the quest for lower gears won't stop at 32, MicroShift already offers road derailleurs ready to shift up to 34-tooth cogs.

Professional riders have been testing the cassettes and providing feedback as they get closer to production time, and the company hopes to begin shipping cassettes to OEMs by the end of the year. No word when QBP, which distributes MicroShift to the U.S. market, will have cassettes in stock for aftermarket sales.

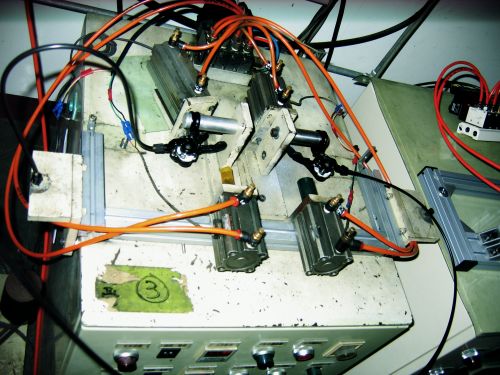

The company is offering no timeline for its electronic drivetrain. Lai says an important part of engineering is seeing how things have been done in the past, what is patented, and then to figure out what MicroShift will do to hit Di2 levels of performance. Various Mavic electric drivetrain-equipped bikes, as well as Shimano Di2, are leaning around its R&D lab as its engineers begin carving out their own take on electric shifting.